Description

The length of the temperature measuring end of this product can be adjusted according to the hole depth, and the terminal and lead protection adopt explosion-proof design, which is safe and reliable. Used for bearing temperature measurement of explosion-proof motors and generators.

Technical parameters

| Temperature measuring end material | Leads | ||||

| Length | Specification | Insulation material | Operation temperature | Shield | |

| Metal | Standard lead length 1000mm User defined non-standard lead length | 2×0.2mm2 3×0.2mm2 4×0.2mm2 | Teflon | -50℃~200℃ | With or without shielding |

Product features:

1. The temperature sensor probe housing of this model can be customized with different lengths and sizes according to the usage environment requirements.

2. The temperature sensor lead material of this model is Teflon, and different models such as shielded and unshielded can be customized according to the usage environment requirements.

3. This model of temperature sensor can be customized with explosion-proof and high-pressure temperature sensors

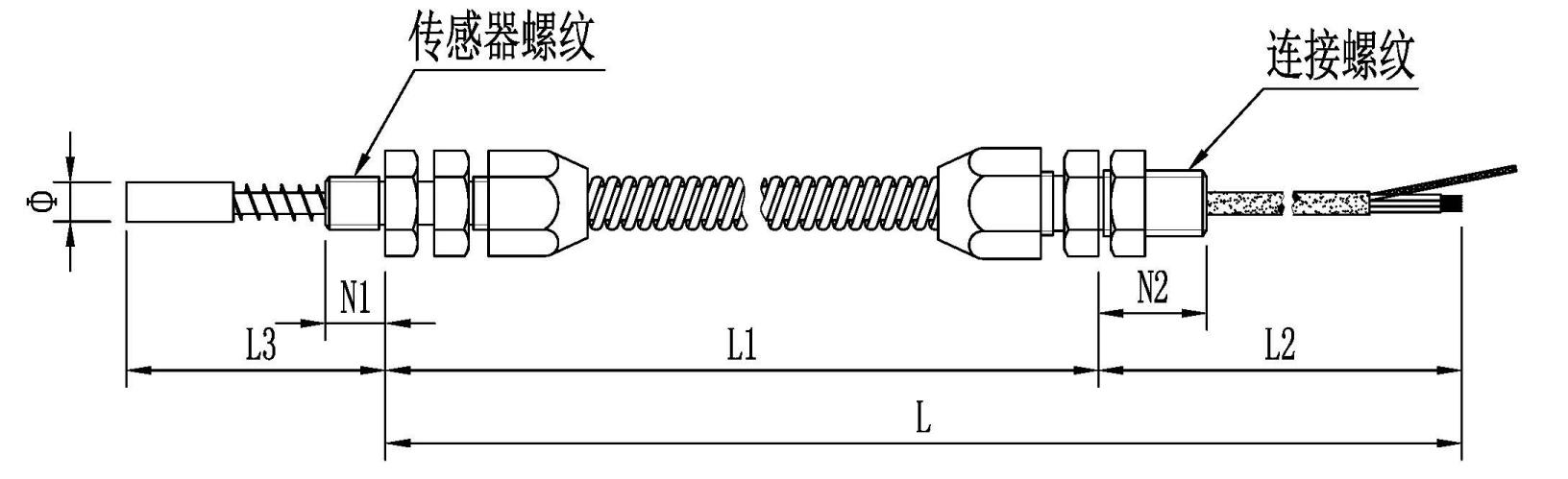

Adjustable

Model Example:WZP-MB1-206 (Prototype number WZPM-206B1)

| WZP | W temperature instrument Z thermal resistance P platinum thermal resistance (P2 is a dual chip) |

| M | Bearing temperature measurement |

| B | B metal protective sleeve C plastic protective sleeve D composite protective sleeve |

| 1 | Adjustable |

| 206 | 2 with fixed device 06 temperature measuring end Φ 6 |

Ordering Example:WZP-MB1-206/55-M12×1-900- M14×1.25-P3×1000

55 | Installation hole depth |

| M12×1 | Temperature measurement end thread specification |

| 900 | Length of protective sleeve |

| M14×1.25 | Terminal thread specifications |

| P | Shielding wire |

| 3×1000 | Three wire system × Line length |

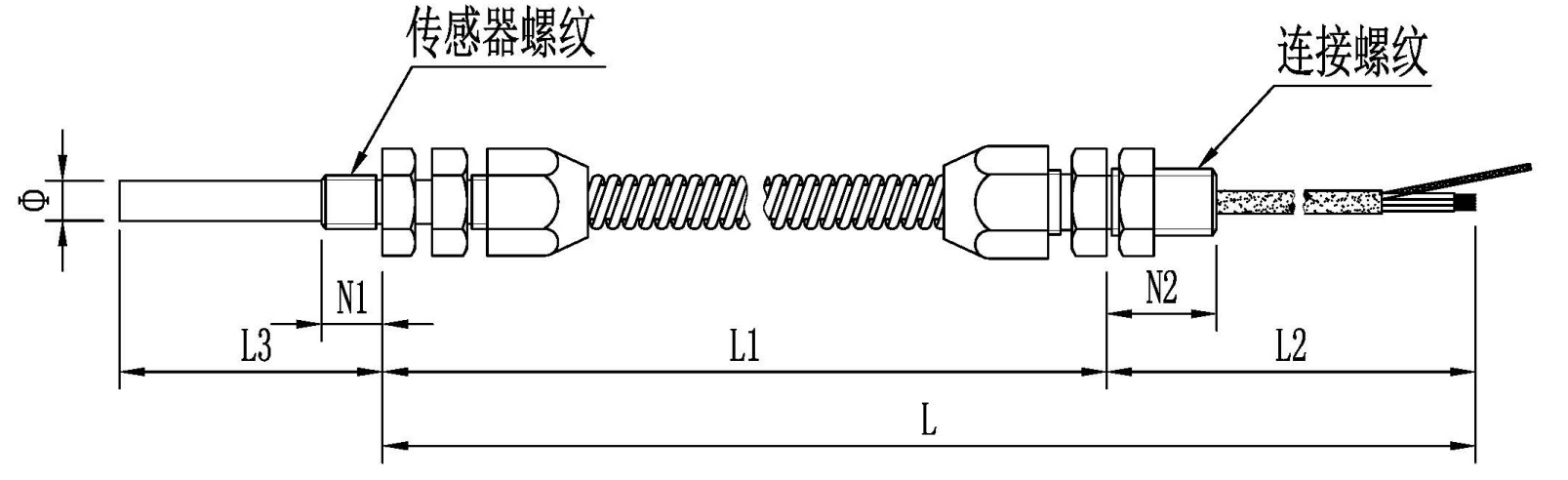

Fixed type

Ordering Example:WZP-MB2-206 (Prototype number WZPM-206B2)

| WZP | W temperature instrument Z thermal resistance P platinum thermal resistance (P2 is a dual chip) |

| M | Bearing temperature measurement |

| B | B metal protective sleeve C plastic protective sleeve D composite protective sleeve |

| 1 | Fixed type |

| 206 | 2 with fixed device 06 temperature measuring end Φ 6 |

Ordering Example:WZP-MB2-206/55-M12×1-900- M14×1.25-P3×1000

55 | Installation hole depth |

| M12×1 | Temperature measurement end thread specification |

| 900 | Length of protective sleeve |

| M14×1.25 | Terminal thread specifications |

| P | Shielding wire |

| 3×1000 | Three wire system × Line length |

Note

3.1 During installation, protect the sensor lead out cable and do not use force to pull it;

3.2 After the installation and connection of the sensor are completed, it is necessary to verify whether the wiring is correct and confirm before proceeding.It can avoid damage caused by strong electricity mistakenly connecting to sensors;

3.3 When the storage period of the sensor exceeds 1 year, the temperature resistance value and insulation resistance value of the sensor should be tested before installation to determine its good performance.

QQ聯(lián)系

QQ聯(lián)系 一鍵撥號(hào)

一鍵撥號(hào) 關(guān)注微信

關(guān)注微信